Building Capability & Capacity

DMTC’s leadership of industry capability development and technology transfer activities closely aligns with Defence’s focus on increasing opportunities for capable, resilient, competitive and innovative* Australian industry suppliers to contribute to national defence objectives and outcomes. [*source – National Defence Strategy 2024]

The Industry Capability Development (ICD) Program is one of the best examples of the way in which DMTC engages across all elements of the national defence industrial sector to build connectedness, scaleability and cyber security in Australian industry.

Benefit to Industry

Participants gain exposure to innovative technologies, best practice techniques and processes and insights into quality, safety and certification standards expected by Defence. The multi-phase ICD Program aims to build capacity and open doors to opportunities in the Defence sector. It also provides mentoring and evidence-based feedback on what SMEs need to do to improve skills.

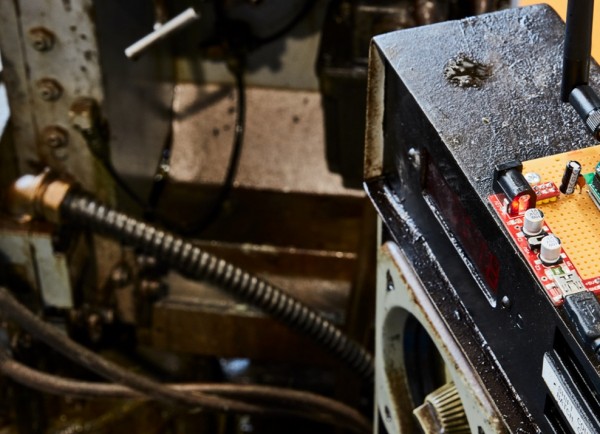

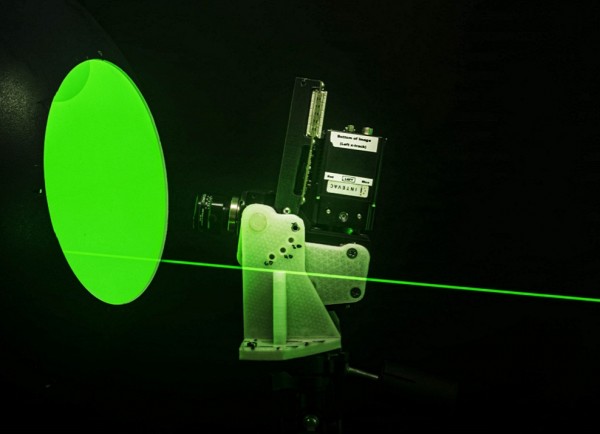

DMTC’s activities focus on development of industry capability, rather than a specific product. As such, platform independent activities (such as welding productivity improvements) can be addressed independently of design or prime contractor selection, focusing on supply chain improvements and setting context through global best practice benchmarks, standards and quality frameworks.

Promotional Video

Investing in future leaders

In line with the workforce challenges being experienced in a range of industry sectors including defence, and in equipping Australian SMEs to leverage the benefits of Industry 4.0 technologies, DMTC has facilitated numerous internships for third or fourth-year undergraduate students in support of the DMTC team delivering the Smart Enough Factory program.

By linking interns like Dylan (see video above) with companies and also with other postgraduate researchers and advisers through DMTC’s Education Program, DMTC is also providing more than just work experience by placing a strong emphasis on broad professional development and networking oppportunities.